Water Tank Lining

Because a water tank is corroded or leaking, it doesn’t automatically mean an expensive tank replacement is required. In many cases professional repair and refurbishment work carried out on the existing tank is a cost-effective alternative.

Specialist Coatings (GB) Ltd provide a full water tank lining service or we can supply the water tank lining materials for use by competent persons. Click here for details.

Our easy to use solvent free epoxy and polyurethane tank lining materials which have been specifically formulated for water tank coatings and water tank lining.

The water tank lining materials are certified, approved and safe for use in all potable water storage applications (contact and use in all types of potable water storage tanks, including tanks made from carbon steel, galvanised steel, fibreglass, concrete, cast iron, plywood, wood & timber).

We provide long-term protective solutions to combat the problem of corrosion and erosion of cold water storage tanks utilising high performance, solvent free technology. Our specialist water tank refurbishment service can restore existing water storage tanks to HSE and Water Supply (Water Fittings) Regulations 1999 standards.

Whether you need a water tank repair, water tank refurbishment, or a water tank coating, Specialist Coatings (GB) Ltd can help.

In-situ water tank refurbishment is far more practical and economical than tank replacement. Corrosion and scale formulation in a water tank can, if left untreated, weaken the structure of the vessel and create conditions for bacteria to form.

In our throwaway society far too often, older cold water tanks are discarded when in reality they can delivery effective service for many more years to come.

We have revitalised many water tanks which would have otherwise been dismantled and destroyed needlessly, with all the cost, hassle and financial implications of removing an old water tank and installing the new one.

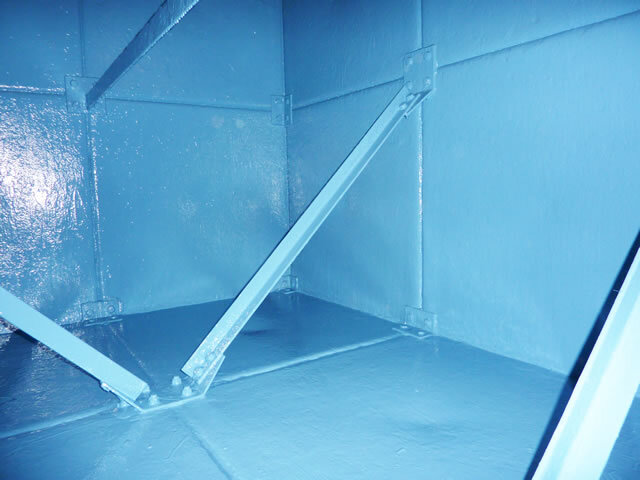

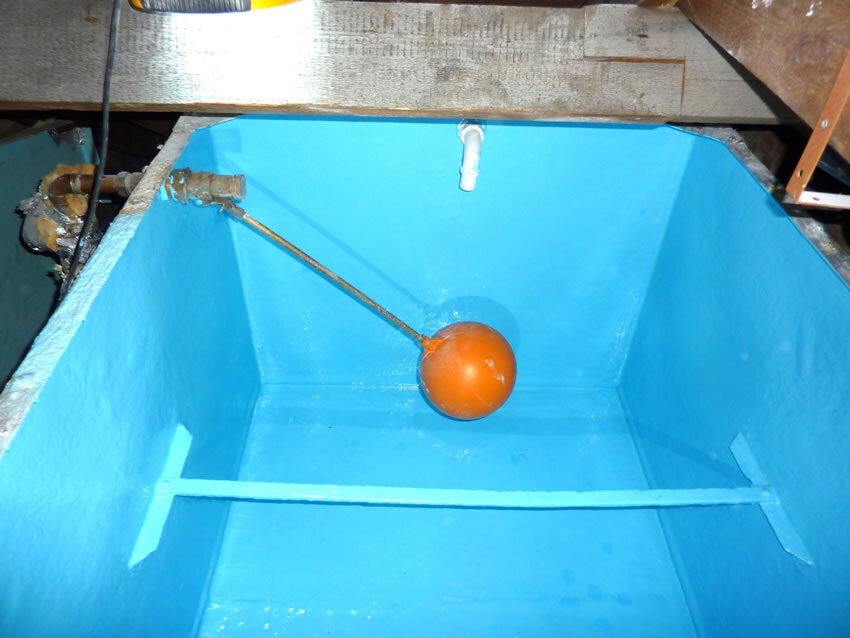

Cold Water Storage Tank, Before and After Tank Lining Treatment

At Specialist Coatings we repair and restore old corroded water tanks with our solvent free glass flake reinforced resin technology, to further the life of the existing tanks by 5 to 20 + years depending on the system used and our customer’s requirements.

In our many years of experience we have refurbished water tanks in every conceivable condition of corrosion, holes and decay with many problems, but we always work with the customer to find the most cost effective solution.

We pride ourselves on our longevity within the industry, and our commitment to restoring corroded and neglected water tanks anywhere in the UK.

There is an efficient and cost effective solution of existing galvanised steel and fibreglass water tanks.

Corroded steel and worn or damaged fibreglass tanks used to store potable or process water can be easily repaired and refurbished using a smooth, easy to clean epoxy lining, which meets current regulations and extends the life of the tank, thus avoiding the need to replace existing tanks.

Bitumen – tanks with pre-existing bitumen lining

Our water tank lining system is completely solvent free and our system can be applied over an existing bitumen paint coating and will not allow the bitumen to bleed through and avoid the risk contaminating or tinting the water.

Cold Water Storage Tank, Before and After Tank Lining Treatment

- Potable water approved

- Avoids costly tank repairs or tank replacement

- Extend the working life of existing water tanks

- The complete tank lining system

- Low odour & solvent free materials

- Safe to use on all potable water storage applications

- Designed for use in confined spaces or difficult-to-reach areas

- Reduction in the potential risk of Legionella and other micro aquatic organisms

- Galvanised steel water tanks (especially the old rusty & leaking)

These water tank lining systems are suitable for:

- Galvanised Steel Tanks

- Potable cold water storage tanks

- Potable fresh hot water tanks

- Braithwaite Water Tanks

- Osmosis, fibreglass tanks with Glass Reinforced Plastic (GRP) – Fibreglass Water Tanks

- Sectional Panel Tanks

- Tanks in difficult-to-reach areas e.g. attics

- Leaking Water Tanks / Rusty Bolts, Support Braces, and Fittings

- Bitumen Lined Water Tanks – Can be lined without the bitumen bleeding through.

Water tanks made from:

- Cement

- Fibreglass

- Mild steel

- Slate

- Stainless steel

- Wood

- Galvanised Steel

- Aluminium

- Carbon steel

- Cast iron

- Concrete

- Brick

Other types of water storage tanks include:

- Rain Water Harvesting Reservoirs and Tanks

- Fire Sprinkler System Water Storage Tanks

- Effluent and waste water tanks and chambers (black water and grey water)

- Avoids costly tank repairs or tank replacement

- Extend the working life of existing water tanks

- The complete tank lining system

- Low odour & solvent free materials

- Tanks with osmosis

- Designed for use in confined spaces or difficult-to-reach areas

- Reduction in the potential risk of Legionella and other micro aquatic organisms

Our water tank lining system provides:

- Solvent-free tank lining system

- Safe and approved for potable water storage applications (cold water storage)

- Prolongs the life of existing tanks

- Easy clean, smooth finish

- Repairs to cracked and leaking tanks

- Capital savings

- Potable water approved

- Minimal disruption

- Low odor and taint free

- Quick completion

- Long-term protection

- Avoids costly repairs

- Minimal disruption

- Reduction in the potential risk of Legionella and other micro aquatic organisms

- Ideal for tanks in difficult-to-reach areas

- A cost-effective repair solution to leaking and corroded water tanks

- Compatible with existing bitumen-based tank paints

Our tank lining system has been developed for both potable and non-potable water storage applications.

It provides long-term protection and extends the working life of the tank. The smooth impervious surface finish of our tank lining system inhibits contamination and the growth of bacteria, including Legionella and micro aquatic organisms.

This usually has serious cost implications and downtime for the owner of the tank and inconvenience to anyone, tenants, etc, who are rely on the supply of water from the tank.

In-situ localised repairs, minimal disruption, quick return to service.

Rather than go to the expense of replacing that tank this can be repaired.

The same applies for the treatment of osmosis when found in a fibreglass tank.

The repair is usually completed in a single day and after testing then the tank returned to service later that same day.

Our tank lining system is suitable for both potable and non-potable water storage use.

Leaking Joints – Repairs to Leaking Bolted Sectional Panel GRP Water Tanks

We often have calls to treat bolted sectional fibreglass tanks that have water seeping or even leaking from the panel joints – invariably the problem is only with the joints and not the open panel surfaces.

In response to this, we have developed a reliable method where the tanks are repaired and stopping water leaks by treating the joints only and avoiding the unnecessary expense of applying a new lining to the entire tank.

Click here to see information about the treatment and repair of fiberglass tanks

Click here for more details on the repair of tanks with leaking joints:

In this Section

- 1Tank Linings

- 2Bund Lining

- 3Water Tank Lining & Tank Joint Repairs

- 4Fiberglass Tanks

- 5Brewery, Winery, Distillery and Food Industry Tanks

- 6Conrete Tanks & Chambers

- 7Hot Water Tanks

- 8Heat & Power

- 9Commercial & Industrial Tank Lining

- 10Marine & Maritime

- 11Narrowboats, Barges, Wide-beams, Canal Boats, Houseboats, Leisure Cruisers & General Water Craft

- 12Steel Tanks

- 13Food & Drink