Narrowboats, Barges, Wide-beams, Canal Boats, Houseboats, Leisure Cruisers & General Water Craft

The past couple of years have seen a big rise in requests for us to supply an increasing number of narrowboat owners (and other water-craft owners too) with the materials and equipment to enable owners to carry out the work themselves

The water tank lining materials are certified and approved and therefore safe to use in all potable water storage applications and is the idea solution for use on narrowboats and other watercraft.

The specialised tank lining materials are based on solvent free, low odour epoxy resins, they have been designed for ease of application/use and use in confined spaces.

They all have a high level of compatibility with range of different surfaces and preparation levels and existing coatings.

Details will be in the Instruction / Guide notes, which are sent by email once the materials have been dispatched.

The primer coat has high anti-corrosion and surface tolerant properties suitable for a wide range of substrates and substrate preparation methods.

The intermediate & topcoat materials provide a smooth easy to clean and flexible surface that will move with the normal movements of the tank, including thermal movement during seasonal expansion and contraction of the steel.

The lining system has exceptionally high properties for impermeability.

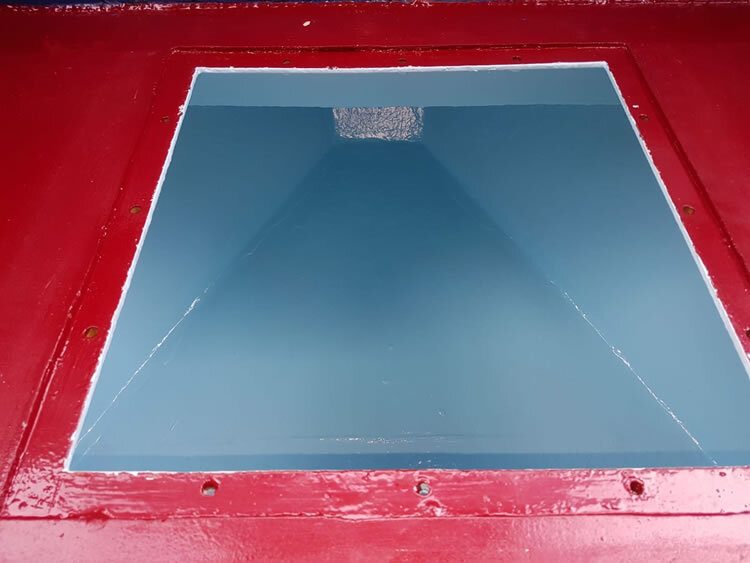

The finish colour would normally be light blue. If you would prefer to have the light grey as the finish colour, please let us know and we amend the order accordingly.

The tank lining system is supplied and applied in different colours for each coat to ensure complete coverage and avoid the risk of misses or area thin coating being applied.

An ever-increasing number of tanks on narrowboats and also hotels, hospitals, schools, wide-beams, barges and other watercraft around the country have been successfully had their potable water tanks lined and restored using this system.

Application in all types of potable water storage tanks, including tanks made from carbon steel, galvanised steel, fibreglass, concrete, cast iron, plywood, wood & timber.

Firstly, our complete system has been designed to be suitable for application with minimal surface preparation and the ability that the work can be carried out / applied whilst the boat remains in the water.

Corroded and rusty tanks and those with deep pitting are not a problem and can all be repaired and given a smooth, easy clean, safe surface.

Tanks with holes in them, can be repaired and made completely watertight again.

Our water tank lining system is completely solvent free and our system can be applied over an existing bitumen paint coating and will not allow the bitumen to bleed through and avoid the risk contaminating or tinting the water.

No restraints on moisture and damp working conditions!

Our tank lining system avoids the need to remove the boat from the water.

This does not apply to this tank lining system There are no humidity or dew point restrictions with this system (and even if there is light condensation of the surface on the steel, it’s not a problem).

It is worth noting that most other tank lining resins would require humidity levels of less than 80% and for boats to be removed from the water to avoid the cold wall effect before applying the lining!!

Treatment of slippery deck surfaces and steps with minimal cost.

We received many photographs and testimonials from boat owners who say how pleased they are with the finished result and how easy it was to apply.

The following set of photographs from the owner of the narrowboat Rhiannon” and clearly demonstrates the different processes and the results that can be achieved by a layperson using this tank lining system, our guide notes, and occasional telephone support.

Support

Unlike other companies, we are happy to give telephone support, even out of hours and on weekends, to help with general guidance, technical questions, or simply moral support. We would rather talk you through something, even if it is confirming that everything is ok, rather than you worrying about something that could be easily fixed with a quick phone call.

Let us have the capacity of your tank then we can calculate accurately the number of materials that you will require.

Suitable for tanks and other surfaces made from:

- Fibreglass

- Carbon steel (mild steel)

- Plywood

- Stainless steel

The lining materials are suitable for and often used for the following:

- Potable water tanks

- Bitumen lined tanks

- Black water tanks

- Chemical tanks

- Diesel fuel tanks

- Drinking water tanks

- Fresh water tanks

- Grey water tanks

- Heavy oil tanks

- Hot water tanks

- Weed trap hatches

Anti-slip surface treatment for steps, ladders, and deck surfaces

Anti-slip and slip resistant surfaces

We offer a supply of tank lining materials directly for trade and professional use and also for DIY applications.

We can supply quantities of resin lining repair kits to make localised patch repairs in tanks with existing resin linings.

Contact us for details and prices.

Because almost every tank is different it is better to contact us directly so that we can advise on the most suitable tank lining materials system for your project and what quantities you would require.

Generally, we would need to know the following:

- What the tank is being used for

- What the tank is made from

- Dimensions or capacity of the tank

We include fully detailed guide note instructions regarding surface preparation and application of the materials when sending out the materials purchased.

Unlimited telephone support

With correct surface preparation and application, the treated tank will extend the working life of any existing tank by many years.

If you have access to abrasive grit blasting then the lining will last even longer.

The processes involved are relatively straightforward:

- Empty and dry the tank

- Brush off loose rust

- Scrape and bang the tank to remove as much loose rust and scale as possible.

- Brush and vacuum the tank

- Apply primer coat

- Apply intermediate coat

- Apply top coat

What information would you need from us to enable you to give me a quote or cost estimate for the materials required to line our water tank?

We need to know or to be able to calculate the internal surface area of the tank in question.

We can do this in two ways:

The first is by the maximum capacity of the tank (litres or gallons).

The second is by the dimensions of the tank. Width, Length and Depth.

(Width across the bulkhead), Length from bulkhead wall to bow point and Depth of the tank from bulkhead wall to tank floor).

From either of these, we will be able to calculate the quantity of materials required.

Also let us know if there are any baffles or additional steelwork in the tank.

Frequent Questions and Answers:

1. Is your tank lining system suitable for cold water tanks?

a. Yes

2. Are your materials suitable for lining fuel tanks?

a. Yes

3. Does the tank have to be removed (from the boat or building) to carry out the lining process?

a. No. Our materials are designed to be used in confined spaces without special equipment.

4. Does the boat have to be lifted from the water to carry out the tank lining work?

a. No. Our materials are designed for use in damp conditions.

5. Is this something I can do myself or do I have to get a specialist in?

a. It does require some practical and technical ability to do this and it does need to be carried out by a competent person. However with the aid of our detailed instructions/ guide notes, which are based on our own extensive experience and years of training people, many people are successfully doing this now and we do provide excellent free technical support via a phone call or, for a small fee to cover our expenses and time, a site visit if required.

6. How long does it take to line a water tank?

a. Usually between 2 and 3 consecutive days

7. Smells: Are there strong smells when working with the resin tank lining materials?

a. No – All the materials that we supply and use are low odor and solvent free and designed for use in confined spaces. See instruction/guide notes for more details.

8. Our tank had once been painted with bitumen. Are your materials suitable for this and will the bitumen bleed through your material?

a. Yes the material is most definitely suitable and is recommended for the lining of tanks that have had a previous bitumen lining. It should be noted that bitumen is no longer approved or allowed for use as a lining for potable water tanks. Our materials are completely solvent free and will lock any remaining bitumen in place and stop any bitumen bleed through.

9. Food & Drink: Are the tank lining materials suitable for food and drink contact us?

a. Yes.

10. Aggressive chemical applications: Are the tank lining materials suitable for aggressive chemical environments such as lining black water tanks and bunded containment areas?

a. Yes. Contact us for details.

Equipment Required

Here is a list of the basic application equipment that you would require for the lining of the tank. Some people do find it useful for us to supply these items because they are the same as we use ourselves. If this is of interest to you then please let us know what you would like and we can include them in the quotation.

- Rust & Surface Chipping Hammer/s, with spring handle for wrist strain reduction.

- Rust Scrappers, with comfort handle & 2″ tungsten carbide blades

- Replacement blades for rust scrappers

- Deep resin scuttles 5ltr 200mm 8″, rectangular

- Resin application Roller frames, short handle 10″ x 100mm (4″)

- Microfibre roller refill heads 100mm (4″) Packs x 10

- Natural bristle brushes for resins 38mm (15”) & 50mm (2″)

- Disposable Nitrile gloves, Box x 100

- Solvent Tool Cleaner x 1ltr bottle/s, Sc-Sol

- Hole filling Thickening Agent, Thixotrope S51, White, bag/pot x 5 to 30g, as required.

- Multi-directional high-strength woven fiberglass (reinforcing) bandage 100mm wide x / linear meter.

Or

Click here for more information on tank lining materials.

Checker Plate Surfaces & Other Slippery Surfaces

The only thing against the checker plate is that it is highly slippery when wet. This applies to other surfaces too.

We have developed a long-lasting high-grip anti-slip coating that we have been applying to steps, ladders ways, and decks that might be slippery. This system can be applied to checker plates as well as wood, steel, and aluminum surfaces.

Like our water tank linings, we have now developed a DIY version that is easily applied.

Contact us for more details and to discuss your project.

Areas of Use

The same lining system can be used as a highly efficient coating or repair system for the following areas:

- Safe and approved for potable water storage tank applications (fresh water tanks)

- Localised repairs to leaking steel or fibreglass tanks

- Bulge water tanks

- Black water tanks

- Fuel Tanks (diesel, petrol, and kerosene/paraffin)

- Engine Room floor and walls (can also be made as an anti-slip coat with high abrasion resistance for high traffic/wear areas)

- External hull coating (completely environmentally friendly and totally resistant to fuel contamination in water).

- A limited range of different colors is available for diffident projects i.e. blacking for the hull external coating and light colours for inside tanks and engine rooms etc.

- Suitable for a wide range of repairs to steel, timber, or fibreglass

- Suitable for repairing leaking pipes

- Potable water usage approved & certified

Contact us for more details and to discuss your project.

Areas of use include:

- Floating homes

- Narrowboats

- Widebeam boats

- Wide beam canal boat

- Dutch barges

- Motor boats

- Leisure Cruisers

- Dutch style liveaboard

- Canal boats

- Houseboats

- Liveaboard

- Barges

- Weed hatch

- Blacking

- Hull protection

- Anti-corrosion

- Minimal surface preparation required

Sealing of unwanted or unused overflow, outlet pipes, or holes found in the tank.

In this Section

- 1Tank Linings

- 2Bund Lining

- 3Water Tank Lining & Tank Joint Repairs

- 4Fiberglass Tanks

- 5Brewery, Winery, Distillery and Food Industry Tanks

- 6Conrete Tanks & Chambers

- 7Hot Water Tanks

- 8Heat & Power

- 9Commercial & Industrial Tank Lining

- 10Marine & Maritime

- 11Narrowboats, Barges, Wide-beams, Canal Boats, Houseboats, Leisure Cruisers & General Water Craft

- 12Steel Tanks

- 13Food & Drink

Recent Facebook conversation thread regarding the narrowboat water tank lining.

Click here or copy and paste one of the following links into your browser:

- https://tinyurl.com/3yar7vhp

- https://www.facebook.com/groups/NarrowboatOwnersGroup/permalink/3333603223584609/

Client Testimonials

“Hello Peter,

I’ve just finished the largest of the two tanks (Grey). I must say that it was a pleasure using your recommended products, the primer especially is impressive. After I had applied one tin of the top coat and then measured coverage per tin it was plain sailing as you had allowed just the right amount of product, I had two tins leftover which is by far better than two short. The client is very happy and also happy to have the two tins for future repairs, although I don’t think he’s going to need them. I’d most certainly be happy to recommend your product in the future, should the need arise.

Many Thanks

Paul”

“Peter,

Sincere thanks for going above and beyond. Understanding the business we are in is positive, being prepared to be more than another supplier is epic. I may make enquiries into local authority needs for your product moving forward.

Kind regards

Michael Walsh

Walsh & Son Ltd“

“Dear Peter,

We have completed the refurbishment of the mixing vessel and the painting of the inside went very well, the final effect was excellent in terms of finish and appearance. Since then we have had our quality assurance audit and the auditor was very impressed with it, he had not seen a vessel treated in this way before but thought it was very effective.

Best wishes

Peter Clough

Director – Bickiepegs Healthcare“