Scarborough Hotel: Galvanised Steel Water Tank Coating

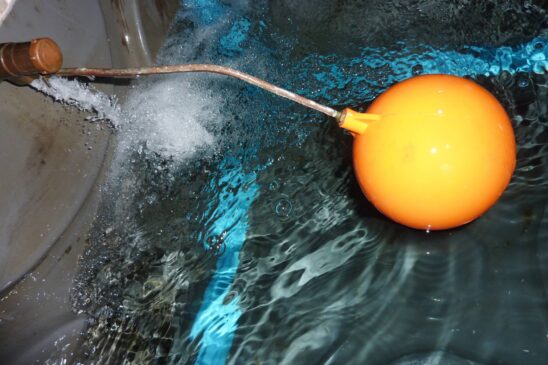

A large hotel in Scarborough had twelve small cold water storage tanks located in two separate attics within the roof void.

The Client

We were commissioned to ensure all the tanks, which were formed from galvanised steel, complied with current water regulations, whilst improving the way the tanks could be cleaned and inspected.

Challenges

- Some of the tanks had been previously coated with a black bitumen tank coating paint, which was failing.

- Nearly all the tanks were old, rusting and generally in poor condition.

- There was limited access in and out of the roof space.

- Several old and disused tanks were left discarded in the attics.

- The hotel was to remain open throughout the entire refurbishment of the tanks.

Solution

Due to the position of the tanks, it would have been very difficult and extremely costly to replace all of the tanks. Our water tank lining system has been specifically developed for in-situ refurbishments and repair for this very reason.

Each tank could therefore be quickly and conveniently brought up to the required standard with minimum disruption and cost. Whilst working on one of the galvanised tanks, we discovered two holes (approximately 20mm and 30mm respectively) under the rust scale on the tank floor. Had we not been working on this tank, it would have failed and started to leak water within a few months. We repaired these holes and reinforced the floor with our resin and fibreglass-based tank repair kit, which will last as long as the tank is in service.

Galvanised steel water tanks – After water tank lining treatment.

Holes in floor of water tank – Before & After tank repair treatment.

The Results

As the hotel remained open to the public, we worked on small batches of tanks at a time to ensure a water supply was still available. The water tank refurbishment process was successfully completed on time and with little disruption to the hotel guests and staff.